Insights About Concept Development And Production Engineering

At Fredricks Design, we have had the pleasure of working across different industries through all phases of successful product and concept development. Our work ranges from automotive, entertainment, consumer goods, furniture, healthcare, and everything in between. As a consultancy, many companies contact us at many phases throughout the product development process. In some programs, we offer turnkey solutions for clients developing new products and brainstorming sessions through manufacturing. We even help marketing teams develop content for digital and print campaigns. In other programs, our reach is limited to a single phase as we help companies conceive new solutions, prototype designs, and develop concepts into production-engineered solutions ready for manufacturing or just about any other area throughout the process.These workflows give us what we believe to be a unique perspective. We have experienced the development process for hundreds of companies across nearly all industries and have identified inefficiencies and leveraged lessons learned as we move on to the next project. Very early on in our company’s history, we found success balancing creative design and technical engineering from the very inception of a project. This balance allows voices from both disciplines throughout the process. It also heads off issues we see when the two disciplines are in separate silos. We still approach our projects the same today and typically reach even further when working with our clients. On a typical program with large clients, we will bring in key stakeholders from design, engineering, marketing, management, sales, manufacturing, end-users, and any other voice we believe needs to be heard to develop a successful product.

Our Conceptual Development Process

The product development process is something that has evolved over the years. Every company has its own version, and every design studio will tell you why theirs is best. Below I have outlined a simplified version of our internal process by phase to better inform you of what we see as one of the biggest problems in what we would consider the typical breakdown of product development.Free space

Research – A deep dive into not only the problem we are trying to solve for end-users but also pain points created internally from current products, market positioning, benchmarking (in and out of the market), and defining opportunities based on current issues, needs, and insights gathered.

Ideation – Brainstorming using key stakeholders listed above to develop new ideas and solutions to current issues and needs.

Concept development

Feasibility and Packaging- Integrating purchased components, existing sub-assemblies, and “slabbing-in” surfaces to understand spatial implications and standards for specific companies or industries. Here we flesh out concepts through high-level modeling and mock-ups we can leverage as we move into detailed design.

Supplier iterations - Gathering feedback from suppliers and key stakeholders to obtain information to help accurately develop the concept package and prepare for production development. This phase is typically viewed as part of the Production Development phase and is a constant source of redundant iterations and costly changes.

Production development

Detailing – Developing concept direction through detailed modeling including final surfacing, developing component thicknesses, attachment features, hardware, draft analysis, and material applications.

Analysis- FEA, weight budgets, swing studies, etc.

Rendering- Photorealistic product representation to solidify final color, material, and finishes.

Drawings and documentation – Assembly level drawings, BOMs, component drawings, assembly instructions, “build books," purchased parts, etc.

With a general understanding of our process, we can get into a key activity that causes the most issues across all industries when developing new products.

The Problem As We See It

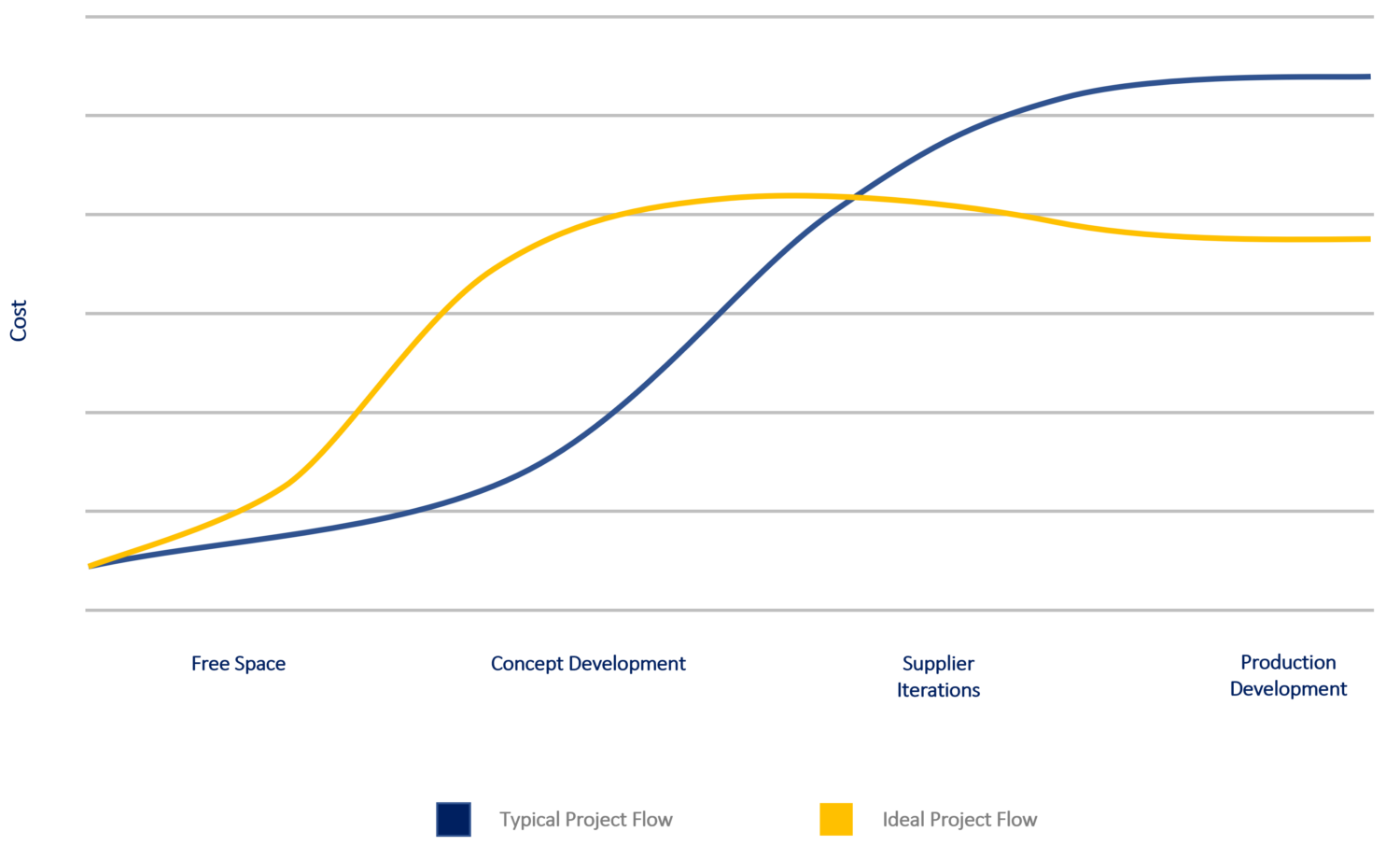

The biggest issue facing clients when we are brought into projects is a lack of time and budget spent on the concept development. This phase is seen as a relatively quick phase that is pushed through to production engineering to move the project down the pipeline and meet the goal delivery date. This thought process tends to lead to one major issue facing our clients, changes in the production phase. Significant changes implemented this late in the development cycle cause three main issues for our clients:

They wreak havoc on budgets and timelines – Changes in this phase tend to include many different disciplines and stakeholders that need input on how to address the issues, which tends to be a nightmare for management and is a bottleneck for keeping programs on track.

They tend to snowball – Simple things like a lack of spatial considerations for a purchased component, fasteners, or a part thickness can quickly snowball outside of one assembly and into another. In production phases, we typically see “frozen” parts or assemblies that are pushed into tooling or manufacturing too soon. This leaves a development team between a rock and a hard place.

The number of players – Conceptual teams are typically small and agile. They can work around issues and have more freedom in the phases leading up to production development than they do once manufacturing partners and suppliers get into the mix. The amount of communication needed to make these changes in production is time-consuming. It also leads to inefficiencies and burns out team members.

Typical Timeline

Ideal timeline

How Does This Apply To The Real World?

To see this in action, look at a real-world example of a common occurrence. Recently, we worked with an automotive supplier to help develop some production seating assemblies for a high-end electric vehicle. Our team was brought in as an extension of the supplier's team to help hit tight deadlines needed to hit production dates. Our scope was to work from the OEM’s A-surface to build a speaker assembly that would mount to the side of a seat with a large motion profile.We quickly fell into discussions with the OEM about A-surface changes that were needed to feasibly construct the parts after offsetting A-surface for leather thickness, foam, and substrate. These changes were not that significant, but due to the nature of automotive, they were sandwiched between seat frames and frozen internal body panels. These discussions quickly grew to make tolerance concessions with manufacturers and concessions on aesthetics with the OEM’s studio. It also took the involvement of multiple other suppliers providing purchased components. We understand that these things happen when working on vastly complicated interiors with many stakeholders, however, these things are much easier to solve before production development where design teams have way more freedom and far fewer stakeholders.

The Solution As We See It

We will never remove all these changes because product development is an iterative process. However, we help position our clients for success by doing our due diligence in the early phases. This involves getting feedback from suppliers, manufacturing partners, and other key stakeholders to head off these issues. In this example, this would have meant positioning ourselves in one of two potential areas to better affect project flow.The first and preferred is with the OEM. Positioning ourselves with the OEM to run packaging and feasibility studies on their interior A-surface before production development would have quickly located areas in the A-surface that would result in non-feasible or expensive tooling conditions. This position would be preferred as direct communication with the OEM studio would result in the quickest turn on any identifiable issues and keep the key stakeholders to a minimum. Positioning ourselves in this way is how we ended up working through the example above. The lack of a direct line to the OEM’s studio was not an effective way to find solutions. Furthermore, this approach would have left the OEM with a more defined package to bring to suppliers to get more accurate quotes and lead times.The second potential area is with the Tier 1 supplier, only earlier in the process. This area is close to the position we were in, but late entry meant that many of the issues we turned up through the production engineering process either required concessions from multiple parties to find a solution or resulted in going back through the chain of communication to see if there was anything we could do with interfacing features to help solve our issues. The key is to identify these issues early in the process, giving us more time to make changes. It also takes fewer players to approve solutions and more accurate packages for quotes and lead times.Our team's unique skillset and deep knowledge of the entire product development process give us an edge when working through the concept development phase. Effective concept development requires an understanding of all manufacturing processes involved in the production of the product. It would be difficult for a team of industrial designers to effectively work through a concept and highlight areas that will likely need to be modified as the project progresses. This is part of the reason we tend to get as many disciplines as possible involved early in the design process in hopes of heading off future issues and reducing late-term changes to the product.

Wrap up

We know we will never have the perfect process for all clients, all industries, and all projects. This key area is just one spot we have seen significant bottlenecks and headaches in our 35-year history. We understand our client's desire to push a product into production as quickly as possible and hit key dates and goals set by upper management, and our solution helps to alleviate just that. You tend to hear around our studio, “haste makes waste." This phrase encapsulates a lot of what we just discussed above, and from our experience, it rarely fails. The simple solution to save time and money is to expand the concept development phase and reduce product development costs.